→ Zippers: A Technical & Visual Choice

Zippers

Choosing the right zipper is not a trivial detail: it is a calculated balance between durability, smoothness, aesthetics, and cost. As a manufacturer, we pay close attention to this element, which can define a product’s perceived quality. Understanding the different types of zippers is essential to making the right technical and stylistic choice.

The 3 main types of zippers

The primary distinction between zippers lies in their “teeth”.

1. Metal Zippers

This is the oldest and most classic type. The teeth are made of metal (brass, nickel, aluminum, bronze) and are individually clamped onto the tape.

Pros: Extremely robust, high durability. Offers a “premium,” authentic, or vintage look.

Ideal Use: The preferred choice for jeans (denim) and workwear requiring heavy-duty strength.

Cons: Heavier and can feel “stiff” or “rougher” to operate than other types.

2. Plastic Zippers

Here, the teeth are made of plastic resin and molded directly onto the tape. The teeth are wider and squarer than those of metal zippers.

Pros: Very lightweight, offers a smooth and fast glide. Available in an almost infinite range of colors, allowing for perfect tonal matches or bold contrasts.

Ideal Use: Perfect for sportswear, streetwear, parkas, and warm jackets.

Cons: Less robust against extreme traction compared to metal.

3. Coil Zippers (or Nylon Coil)

The “teeth” are not individual elements but a continuous spiral of nylon or polyester sewn onto the tape.

Pros: Extremely flexible, lightweight, and discreet. This is the basis of the invisible zipper (where the coil is concealed on the back of the tape), widely used for skirts, dresses, and hidden pockets.

Ideal Use: Pockets, skirts, dresses (invisible style), linings, and anywhere flexibility is required.

Cons: Less durable than metal or molded plastic for heavy-duty usage.

Colors & Pullers

Once the chain type is chosen, customization begins.

Choosing the Width (Zipper Gauge/Size)

The width, or “size,” of a zipper is designated by a number (e.g., #3, #5, #8). This number corresponds approximately to the width in millimeters of the teeth when the zipper is closed.

Size #3 (Fine): Skirts, dresses, trouser pockets.

Size #5 (Standard): The most versatile size, used for jackets, coats, backpacks, and zip-up hoodies.

Size #8 or #10 (Heavy): Parkas or heavy-duty jackets.

Color Selection (Teeth & Tape)

The visual impact depends on the color combination of its two components:

The Tape: The fabric part (usually polyester) sewn to the garment. It can be dyed in any color to match the main fabric perfectly (tonal) or to create a strong visual contrast.

The Teeth:

Metal: Various finishes available (silver nickel, gold brass, antique bronze, blackened “gunmetal,” etc.).

Plastic/Coil: Can be the same color as the tape (most common) or a different color for a design effect.

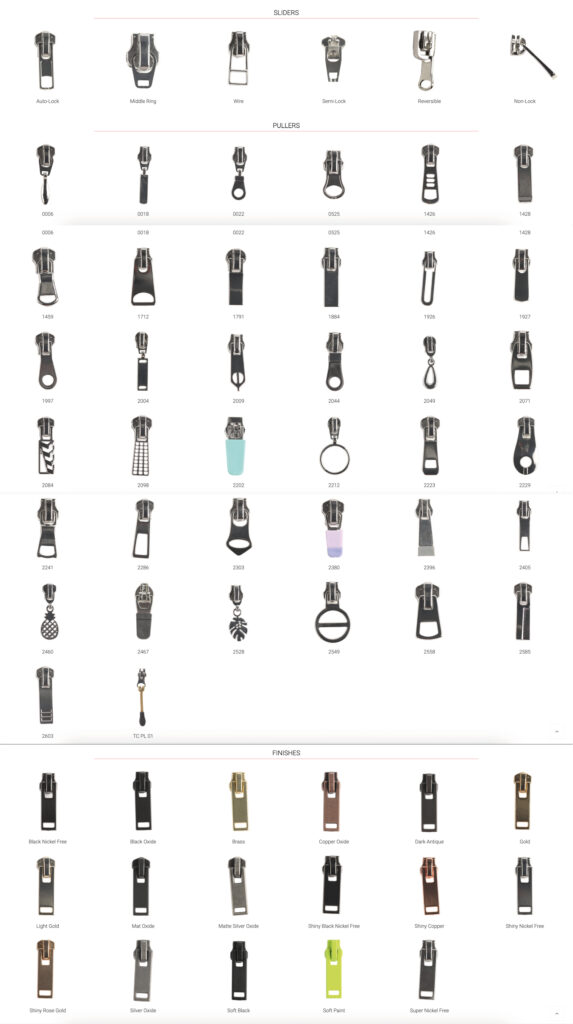

Choosing Sliders & Pullers

The Slider: The mechanical piece that moves up and down to open or close the teeth. It can be “auto-lock” (standard for clothing, it stays in place), “semi-auto lock,” or “non-lock” (typically for bags).

The Puller (Pull Tab): The most important customization point for brand image. While standard metal pullers are functional, we can provide fully custom pullers: laser-engraved with your logo, molded into a unique shape (metal or plastic), or enhanced with a cord or rubber tab (very common in sportswear).